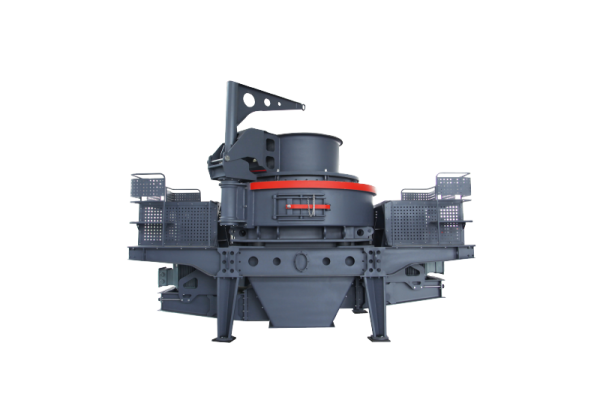

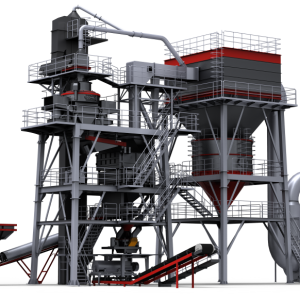

Performance

« Rock On Rock » And « Rock On Iron » Crushing

In order to meet the crushing demand of different customers, VSI6X Sand Making Machine takes two crushing methods— « rock on rock » and « rock on iron »(which refer to « rock hitting rock » and « rock hitting iron » respectively). The material liner of « rock on rock » and counter block structure of « rock on iron » are designed specially according to the working condition of the sand-making machine, which greatly promotes the crushing ratio of the sand maker.

New Structural Designs of Key Parts

In order to ensure the overall performance of the sand making machine, key parts on it is optimized on their structures, such as the impeller, the bearing cylinder and the main body. Several national patent technologies zenith owns ensure the high yield, high efficiency and low cost of the crushing machines in crushing operation.

Lower Costs in Usage and Maintenance

VSI6X Sand Making Machine is optimized on some structures and crafts of the impeller. The service life of some wearing parts is prolonged by 30~200% compared to the previous crushing machines under the same usage conditions. VSI6X Vertical-shaft Sand Maker is configured with simple lifting device. When the sand maker needs maintenance, the lifting of the impeller and the bearing cylinder needs no extra-large lifting devices, greatly lowering the maintenance difficulty of the sand maker.

Safer and More Reliable Operation

When designing this sand making machine, the safety and reliability are taken into consideration. The more stable and reliable dual-motor drive and automatic diluted oil lubrication are adopted and at the same time, the gunk and the maintenance platform are optimized to ensure the safety and reliability of operation.

Digitalized Processing, Higher Precision

There are tens of lines of numerical controlling machine tools. Operations such as steel plates’ cutting, bending, planing, milling and paint spraying are all controlled numerically. The machining precision is high, especially for the core parts.

Sufficient Supply of Spare Parts, Worry-free Operation

zenith, whose businesses cover production and sales, takes responsibility for every machine produced by ourselves. We can offer customers technical services about products and original spare parts to ensure the worry-free operation.

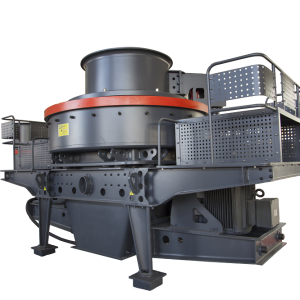

Working Principle

VSI6X Sand Making Machine (also known as « Sand Maker ») has two feed modes – « feed at center » and « feed at center & sides ». As for the former mode « feed at center », materials at the feed hopper firstly pass through the central hole into the high-speed spinning rotor. In the rotor, materials are fully accelerated and thrown outwards from the launching port to collide with a part of materials that freely fall after rebound. Next, materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening. As for the latter mode « feed at center & sides », firstly, materials at the feed hopper pass through the circular hole. Then, materials are divided into two parts by the distributing tray. One part of materials enter the high-speed rotating impeller while the other part of materials fall from all sides of the tray. Materials in the impeller would be accelerated rapidly and thrown outwards at a high speed to collide with materials falling from all sides of the tray. Next, all materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening.