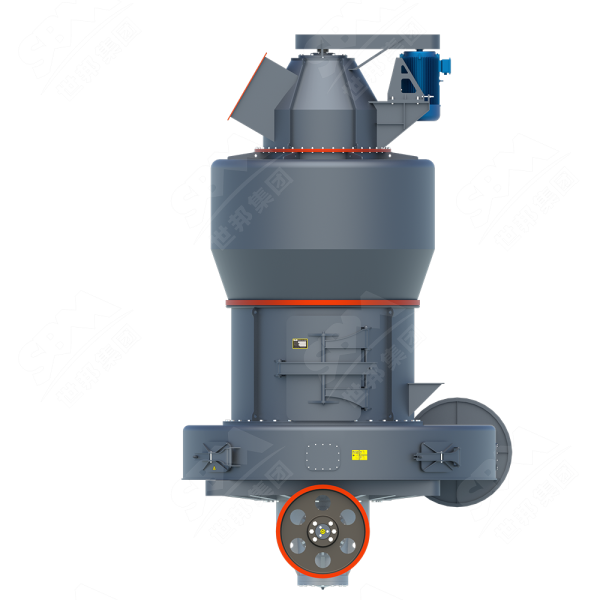

MTW European Trapezium Grinding Mill

MTW European Grinding Mill is innovatively designed through deep research on grinding mills and development experience. It absorbs the latest European powder grinding technology and concept, and combines the suggestions of 9158 customers on grinding mills. This grinding mill perfectly satisfies the production demands of the customers on 200-33μm (80-425Mesh) fine powder.

Product Features: Lower operational & maintenance costs, excellent environmental protection, better quality of finished products

- Input Size: 0-50mm

- Capacity: 3-50TPH

- Material: Limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

Description

Performance

Excellent Quality of Final Powders, High Production Efficiency

MTW European Trapezium Grinding Mill adopts unique split-type shovel blade. It is cambered. Its use effectively enlarges the working area and further improves the production efficiency. Besides, MTW European Trapezium Grinding Mill adopts unique pneumatic sealing device, which can effectively eliminate the « coarse powder spilling », so the quality of final products get controlled well.

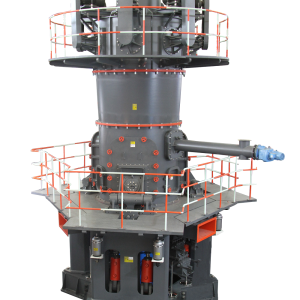

Small Occupational Area, Pollution-free Operation

MTW European Trapezium Grinding Mill takes whole transmission by bevel gear. The structure is more compact, occupying smaller floor area. Meanwhile, equipped with professional dust remover, zenith’s MTW European Trapezium Grinding Mill boasts excellent effect of dust removal and low concentration of dust emission, friendly to environment protection.

More Wear-resistant Vulnerable Parts, Higher Using Ratio

The grinding rollers and rings made of wear-resistant alloy are developed by zenith and scientific institutes together. Their service life is 1.7-2.5 times longer than traditional rollers and rings made of high manganese steel. Part of vulnerable spare parts adopt split structure which is helpful to save more expenditures on vulnerable parts.

Lower Energy Consumption – Cambered Air Duct

MTWEuropean Trapezium Grinding Mill uses the cambered air duct with low resistance. By this, air flow enters the grinding mill tangentially. Compared with traditional straight air ducts, the inlet of this air duct is smooth with little resistance and the outlet is easy for the dispersing of materials which can avoid material piling, effectively reducing energy consumption of the system.

Digitalized Processing, Higher Precision

There are tens of lines of numerical controlling machine tools. Operations such as steel plates’ cutting, bending, planing, milling and paint spraying are all controlled numerically. The machining precision is high, especially for the core parts.

Sufficient Supply of Spare Parts, Worry-free Operation

zenith, whose businesses cover production and sales, takes responsibility for every machine produced by ourselves. We can offer customers technical services about products and original spare parts to ensure the worry-free operation.

Working Principle

After jaw crushers break large bulky materials to smaller ones, elevators work to send materials to the hopper. Then, by electromagnetic vibrating feeders, broken materials are evenly and quantitatively sent to the grinding chamber of MTW European Grinding Mill. After grinding, materials are blown away by airflow to the powder concentrator for classifying. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. And, after that, the airflow would go into the fan along with the air return duct at the top of cyclone power collector. This system adopts a closed circuit and runs under positive and negative pressure. Because materials have a certain content of moisture, heat generated during grinding may lead air evaporation or swell in the grinding chamber so that the amount of airflow increases sharply. Besides, if the feed port and joints of pipelines are not sealed well, external air may intrude the grinding mill and lead imbalance of airflow. So, zenith arranges exhaust valves at the air outlet of the fan to induce redundant air into the bag filter. After purifying, the redundant air is discharged. This arrangement can achieve both the balance of airflow and the eco-friendly production.