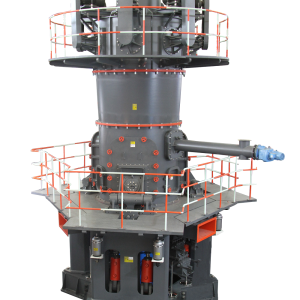

MRN Pendulum Roller Grinding Mill

According to accumulation and experimental analyses of on-site test data for more than thirty years, zenith, a Chinese grinding mill manufacturer, has researched and developed the fifth-generation pendulous hanging grinding mill – MRN grinding mill. All non-combustible and non-explosive brittle mineral products whose Moh’s hardness are below Grade 7 and water content below 6% could be ground by this grinding mill.

Product Features: Lower operational & maintenance costs, excellent environmental protection, better quality of finished products

- Input Size: 0-55mm

- Capacity: 2.7-83TPH

- Material: Limestone, calcite, dolomite, petroleum coal, gypsum, barite, marble, talc, coal powder, etc.

Description

Performance

Lower Maintenance Costs – Grinding Roller Adopts Dilute Oil Lubrication

Grinding roller of MRN Pendulum Roller Grinding Mill l adopts diluted oil lubrication. It is a technology initiated domestically which is maintenance-free and easy to operate. Diluted oil lubrication is oil bath lubrication, more convenient than grease lubrication since no frequent oil-adding, and it needs lower maintenance cost.

Higher Grinding Efficiency – No Shovel Blade Cylinder

There is no shovel blade cylinder in the grinding chamber of MRN Pendulum Roller Grinding Mill, so the ventilation area is larger and air-conveying resistance is smaller. Besides, use of large-diameter grinding roller directly improves the efficiency of the grinding mill.

More Stable Operation – Elastic Volute Damping Structure

Elastic volute damping structure can effectively reduce vibrating damage on the MRN Pendulum Roller Grinding Mill. Between the volute and engine base, special elastic structure is applied, and in combination with setup of rubber shock pad, it could directly avoid influence of vibration of engine base on operating stability of powder concentrator, and completely eradicate the problem of shatter crack of volute and central engine due to vibration of engine base.

Lower Energy Consumption – New Cage-Type Powder Concentrator

Powder concentrator of MRN Pendulum Roller Grinding Mill adopts low-resistance hanging cage-type powder concentrator. The advantages of this powder concentrator lies in its high efficiency and low energy consumption. Processing same kind of materials and requiring same fineness, this powder concentrator needs less electricity but it can bring higher capacity compared to the blade-type powder concentrator.

Digitalized Processing, Higher Precision

There are tens of lines of numerical controlling machine tools. Operations such as steel plates’ cutting, bending, planing, milling and paint spraying are all controlled numerically. The machining precision is high, especially for the core parts.

Sufficient Supply Of Spare Parts, Worry-free Operation

zenith, whose businesses cover production and sales, takes responsibility for every machine produced by ourselves. We can offer customers technical services about products and original spare parts to ensure the worry-free operation.

Working Principle

After hammer crushers (or jaw crushers) break large bulky materials to smaller ones, elevator works to send materials to material hopper. Then, by electromagnetic vibrating feeder, broken materials are evenly and quantitatively sent to the grinding chamber of MRN Pendulum Roller Grinding Mill. After grinding, materials are blown away by airflow to the powder concentrator for classifying. Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. And, after that, the airflow would go into the fan along with the air return duct at the top of cyclone power collector. This system adopts a closed circuit and runs under positive and negative pressure.